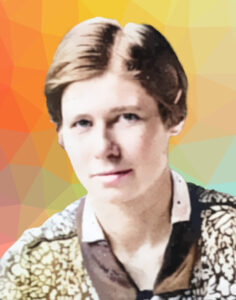

Occupation

English Metallurgist (a type of Materials Science Engineer) and Crystallographer (determines the arrangement of atoms in crystalline solids)

Birth/Death Dates

February 16, 1894 – December 14, 1995

Summary

Constance Tipper investigated brittle fracture and the ductile-brittle transition of metals used in constructing warships. She was the first female to hold a full-time faculty position at Cambridge University’s Department of Engineering.

Educational Background

Saint Felix School, a 2-18 boarding school in Southwold, England

Newnham College of Cambridge University in Cambridge, England (studied engineering and graduated with a Third in Natural Sciences)

Struggles this Innovator Overcame

In 1923, under her maiden name, C. F. Elam, Tipper, and famous scientist Geoffrey Ingram (G.I.) Taylor received the Royal Society’s Bakerian Medal for their research on the distortion of aluminum crystals under tension. The Royal Society did not initially realize that Tipper was a woman. Their dinner club did not allow female attendees, so she was prevented from attending the celebratory dinner intended to honor her and Taylor.

Problems this Innovator Solved

During World War II, brittle fractures were discovered in Liberty Ships. Liberty Ships, built in the US between 1941 and 1945, were the first all-welded prefabricated cargo ships. They were used to transport essential supplies across the Atlantic. When several of these ships started to develop large cracks, it became an urgent naval problem. Tipper was asked to figure out why these ships were cracking. Many people incorrectly assumed the breakage resulted from the welding or fabrication process used to make these ships. Tipper discovered that the fractures were caused by the properties of the steel itself and not by the welding. The steel became dangerously brittle at low temperatures. This made the ships especially susceptible to brittle failure when crossing the Atlantic, where they were subjected to low temperatures. Tipper developed what is now known as the “Tipper Test” to measure the brittleness of materials.

How this inventor changed the world (or at least their corner of it)

The research Tipper conducted with Taylor on aluminum crystals formed the groundwork for modern dislocation theory. Tipper was the first to use a scanning electron microscope (SEM) to investigate fractures in metallurgical research.

Tipper’s accomplishments include over 80 published papers and numerous awards. She held positions at the Royal School of Mines, the Royal Institution, the Davy Faraday Laboratory, and the Cavendish Laboratory at Cambridge.

Lasting changes from this inventor’s work or how they trailblazed

Tipper is highly regarded for her groundbreaking work on the brittle fracture in Liberty Ships during World War II and for developing the Tipper Test. The Tipper Test measures the temperature when a material goes from being flexible to breaking suddenly. The Tipper Test is now the standard for determining this form of brittleness in steel.

Tipper proved that at a critical low temperature, the fracture mode in steel changes from ductile to brittle. Her research improved the quality of the steel and welds used in shipbuilding and resulted in improvements in engineering structures, such as bridges, aircraft, and nuclear power plants.

Tipper’s work supported further research into the behavior of materials under stress and led to the development of new technologies and techniques for testing and analyzing materials.

She promoted the study of materials science to young people, particularly women, and encouraged them to pursue careers in science and engineering.

Tipper’s alma mater, Newnham College, celebrated her 100th birthday in 1994 by planting a Tipper Tree, a sweet chestnut.

https://en.wikipedia.org/wiki/Constance_Tipper

https://www.imperial.ac.uk/Stories/constance-tipper/