Please provide a summary of your job or research. What is an average day like? What are some duties performed?

I am currently a Product Manager for Parker Hannifin Tube Fittings Division. As a PM, you tend to get involved in all areas of the business – sales, marketing, operations, supply chain, engineering, and accounting – all while being the customer-facing lead for your product. In any given day, I may be visiting a customer to solve an engineering problem, pitching a new product to internal and external shareholders, working on new product development with engineering, or creating a new marketing strategy. It is a very dynamic role—it requires active listening and understanding of the customer and their pain points as well as internal communication, collaboration, and leadership to get things done. One of the best things you can learn from Edheads is a framework for critical problem solving (you will have to solve problems no matter what your future holds).

What is your educational background and what prompted you to go this direction (why are you where you are instead of a completely different career somewhere else?).

MBA from UCLA Anderson School of Business

MS in Mechanical Engineering from Miami (OH) University

My strengths in school were always math and science and I was always driven to understanding how things worked. I remember being the 5 year old that took everything apart down to the circuit boards just to see how it all went together. I ended up following my strengths into a degree in Mechanical Engineering. Engineering was a great degree because it combined what I was good at, but more so, helped me realize an interest in creating things and leading teams.

In my undergraduate and later during my MBA I always found myself helping to lead small teams to create new products or proposals. I wasn’t always the “best” engineer or designer, but I did always have a way of finding out how to bring people with different strengths together to form great teams.

What have you struggled with or overcome in your educational path or life path to get to this point?

In college, probably like most incoming Freshman, I had no idea what I wanted to study or do in life. I leaned on my strengths early on (math and science) and discovered engineering as an interesting path and degree. However, even as I studied engineering I knew I didn’t want to be a typical engineer after school. I wanted to be in the STEM field, where I saw exciting things being made and important problems to solve, but I always kind of knew that I would need to consider how to combine my business interests in a future career. This was not always easy, and is something I am constantly working on, but I think the best way to navigate this is to just talk to people as early and often as you can, something I could have done more. Talk to your teachers, friends, family, classmates, industry professionals. Ask questions. There will always be people willing to help navigate the important things like school and careers. All it takes is some courage and drive to ask.

What is the best part of your job/research?

I love that no two days are the same and that I get involved with such a wide range of projects and departments. I always knew I never wanted to be a traditional design engineer and wanted to get more immersed with the customer and helping to solve their problems.

What is the worst part?

It can be challenging to have a great idea but maybe not have the resources or the time to invest in it.

What’s the most exciting part of your job?

I love working with people and seeing a new product from start to finish. It’s really great to see something you’ve worked on be appreciated by a customer and used for the benefit of others. It’s even more rewarding when you can do that within a collaborative team environment.

What’s the most exciting work/research related thing that has happened to you?

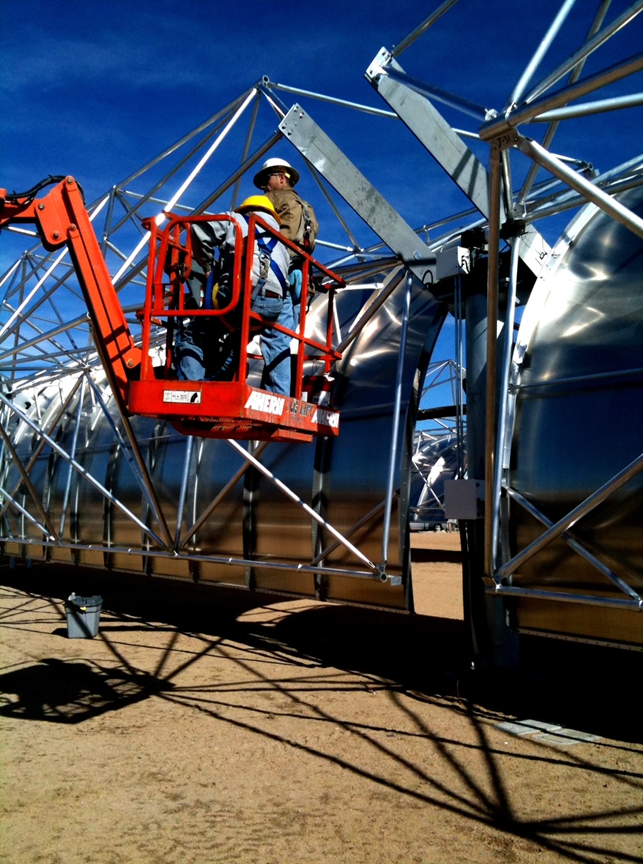

One of my favorite customers I got to work with was SpaceX. We worked very closely over the years and I got to visit their facility many times and work with some very smart people on a specific design function for their launch pads.

What has changed about your profession in the past ten years?

There has been a lot of changes in the Motion & Control space. First, the industry is aging quite a bit and we’ve seen a huge influx of the younger generation getting involved in a historically mature industry. With workforce turnover you certainly lose a lot of expertise, but it’s also given the industry a bit of exciting energy around the future. Second, the technology itself has changed and we’re seeing a major trend in electrification, Internet of Things (IOT), electronic controls, etc which will be very interesting to see how it all develops in the years to come.

What do you think will change in the next ten?

Certainly, there will be more advancement around Internet of Things (IOT) and integrating large-scale industry with the cloud. I also think the electrification trend will continue across mobile vehicle platforms.